Time of Execution

2013

Client

Novio Packaging A/S

Status

Design licensed to US and Canadian manufacturers of healthcare equipment

Design Team

Jonathan Rasmussen, Marie Berggreen, Joen Rommedahl, Frederik Hansen

Keywords

Plastics design, injection moulding, rheumatic diseases, healthcare

Design Brief

It is expected that child-safe features will be required by law for all healthcare related packagings in near future. Such mechanisms typically make the packaging harder to open. We aimed to develop a pill bottle for vitamins and supplements that incorporates child-safe features but still allow people living with rheumatic diseases and limited hand dexterity to easily extract the pills.

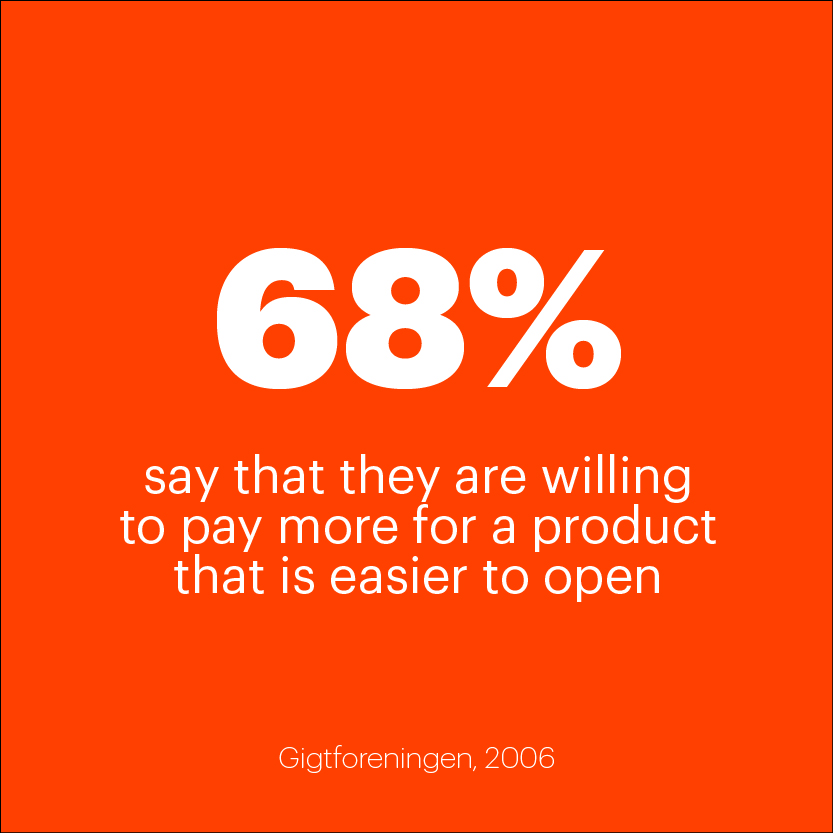

“Internationally, we see a profound tendency towards a future market where consumers are willing to pay more for well designed products”

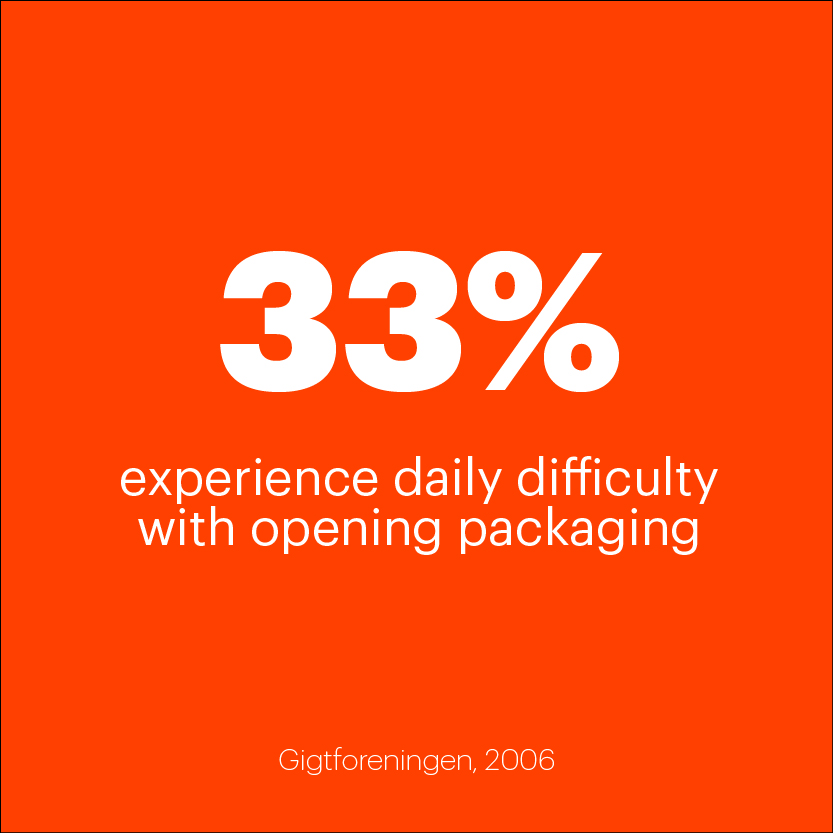

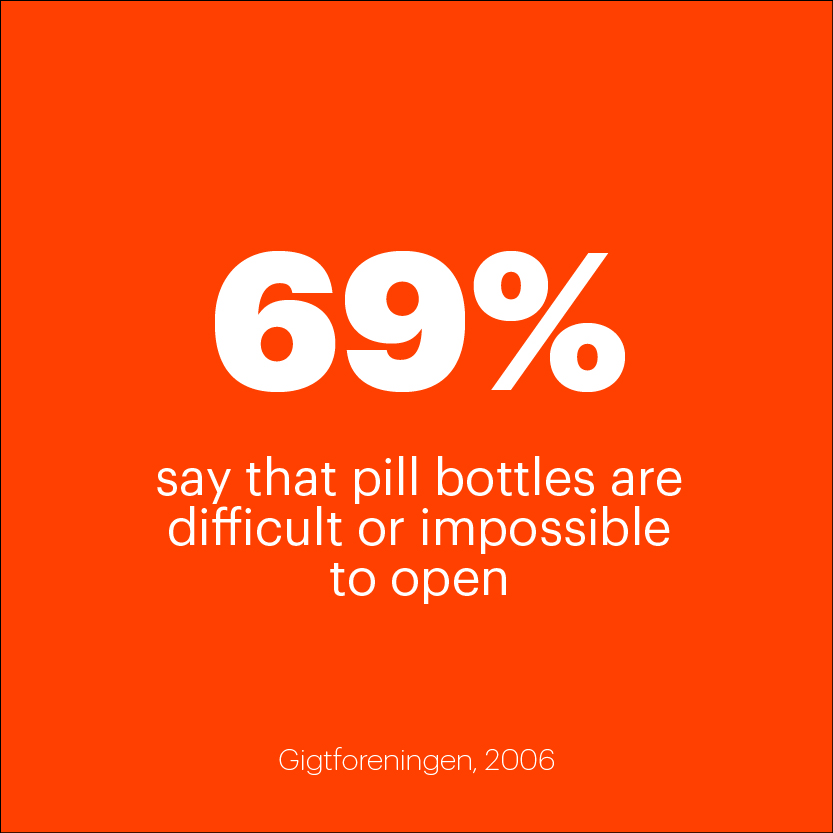

Problem Research

In recent years, the media has directed attention to the accidental poisoning of children through overdosis of vitamin pills.

The problem is also recognized by Børneulykkesfonden whos mission it is to make Denmark a leading country in child safety.

Clearly, there is a need for more child-safe protection of healthcare products such as vitamin pills. But how do you ensure that such safety mechanisms will not further disable elderly and people living with rheumatic diseases when handling the products? We set out to explore their difficulties by reading scientific studies and conducting interviews.

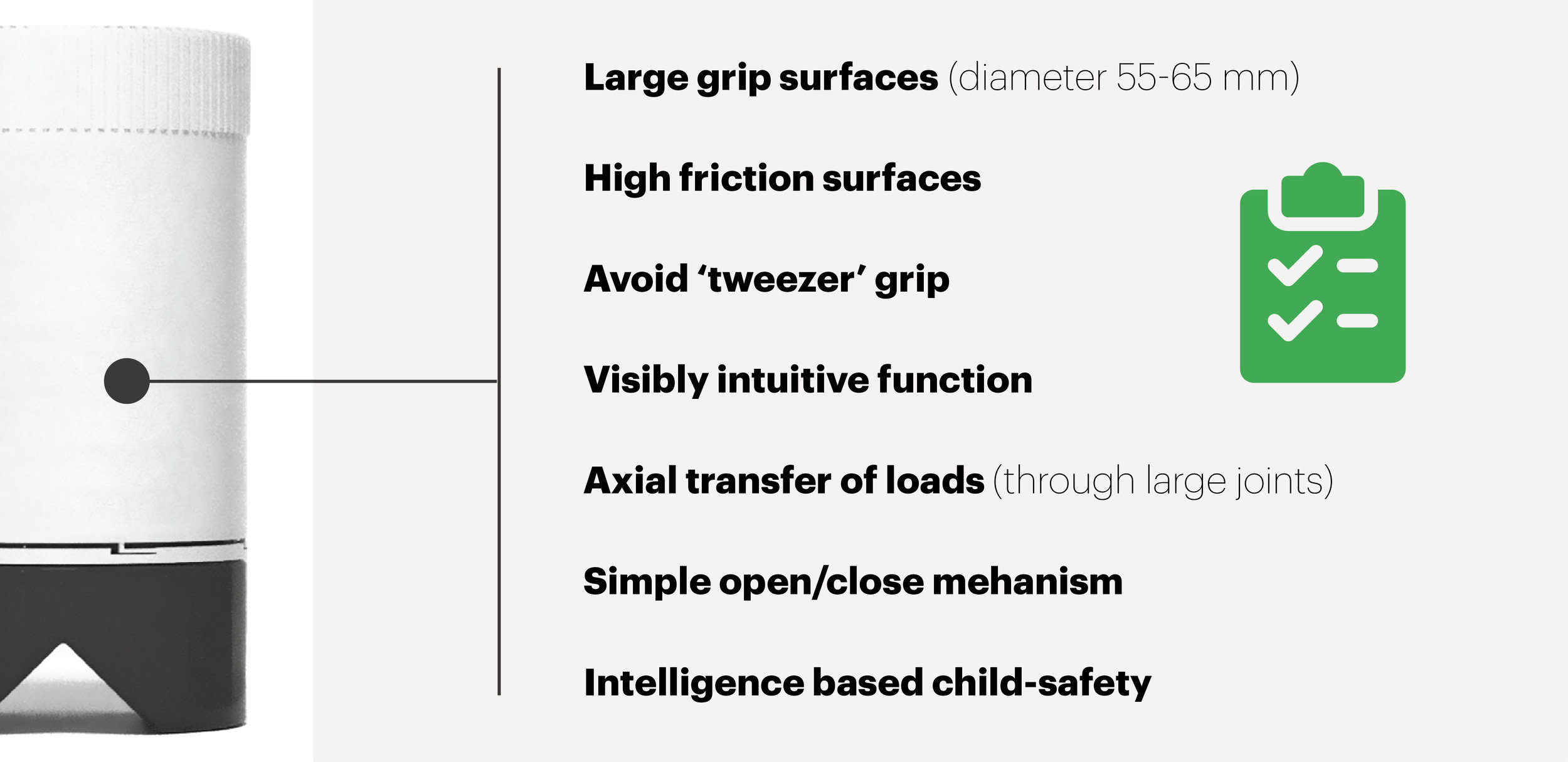

From our research, we established a list of design parameters that can be improved for easier handling.

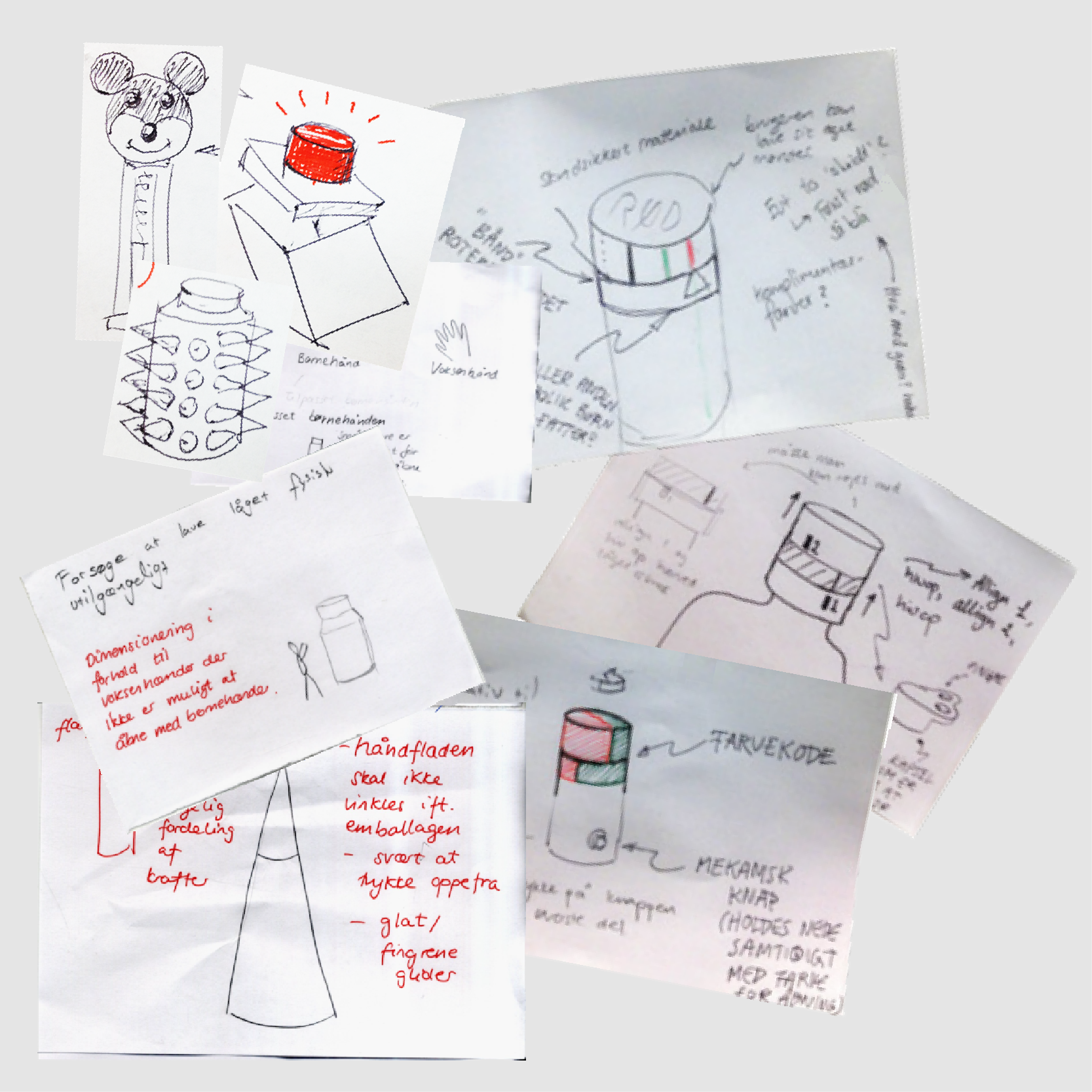

Conceptualization

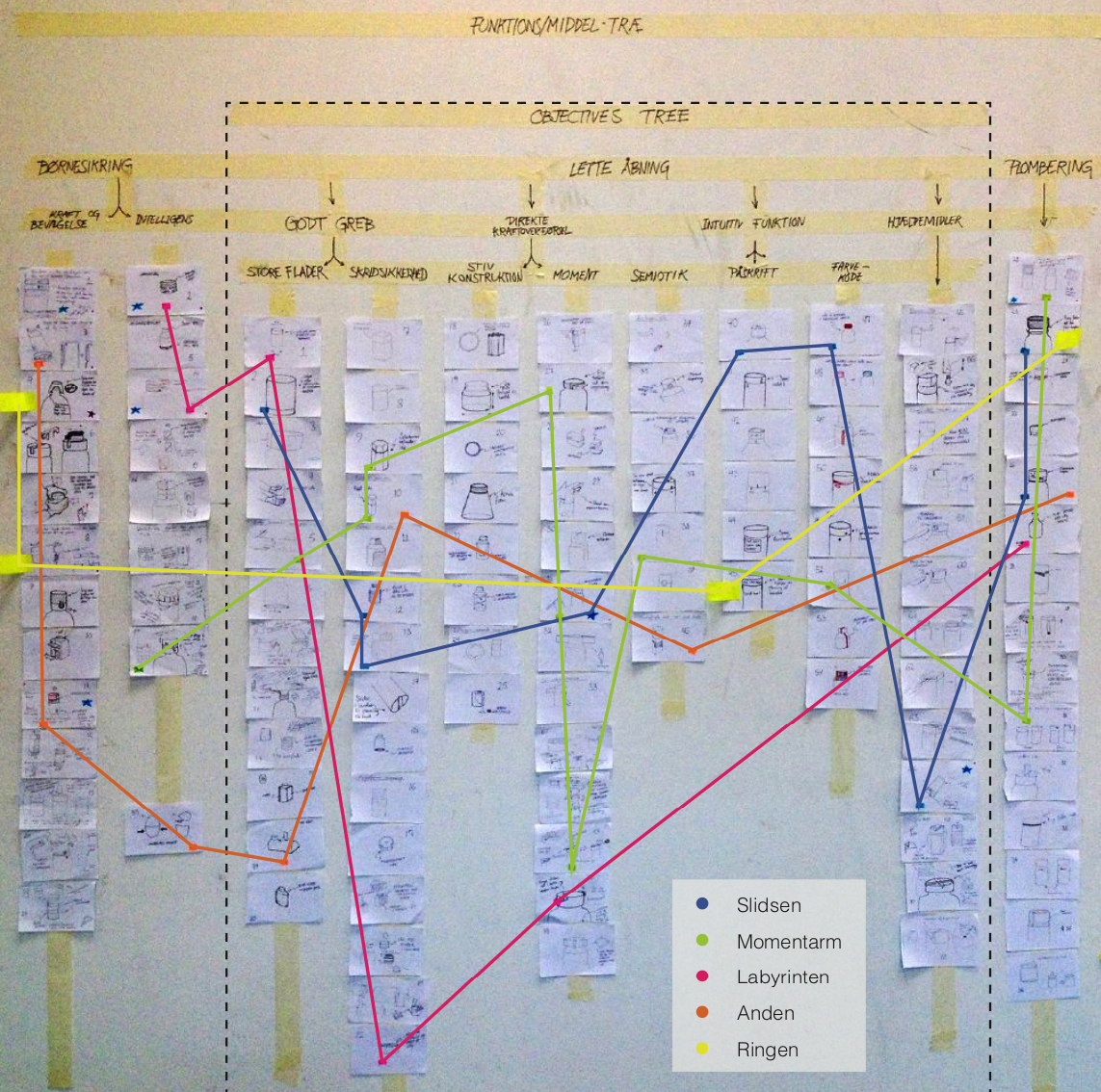

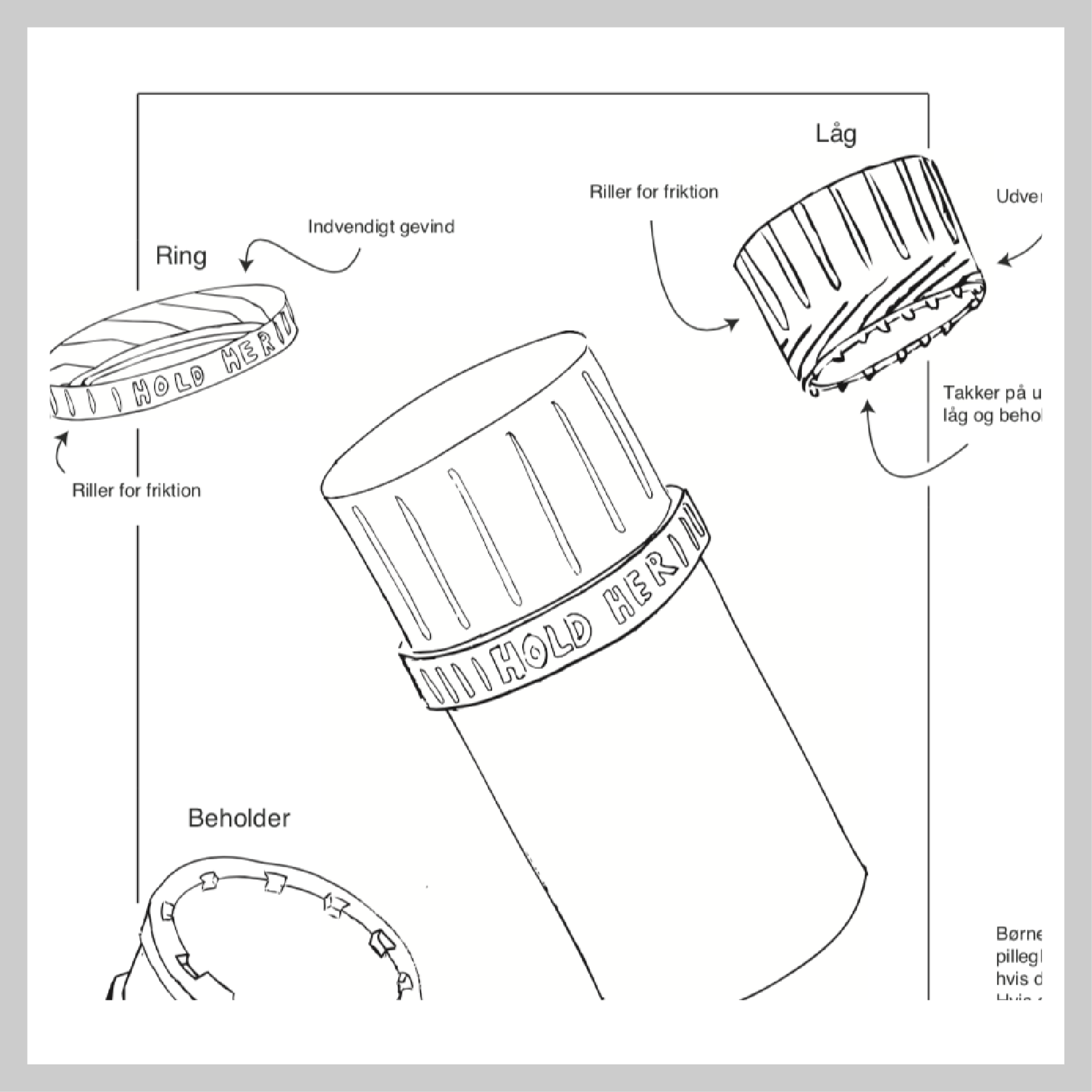

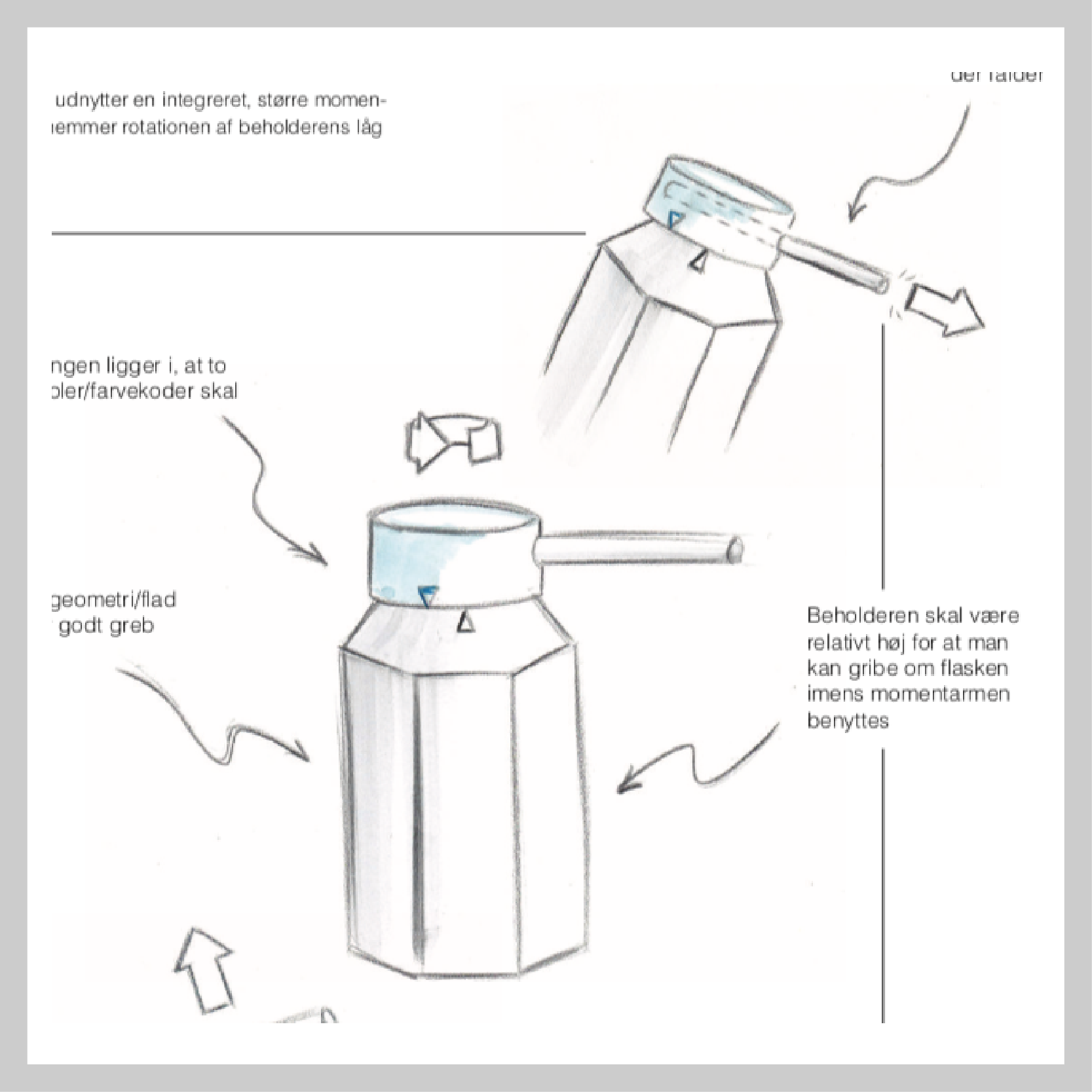

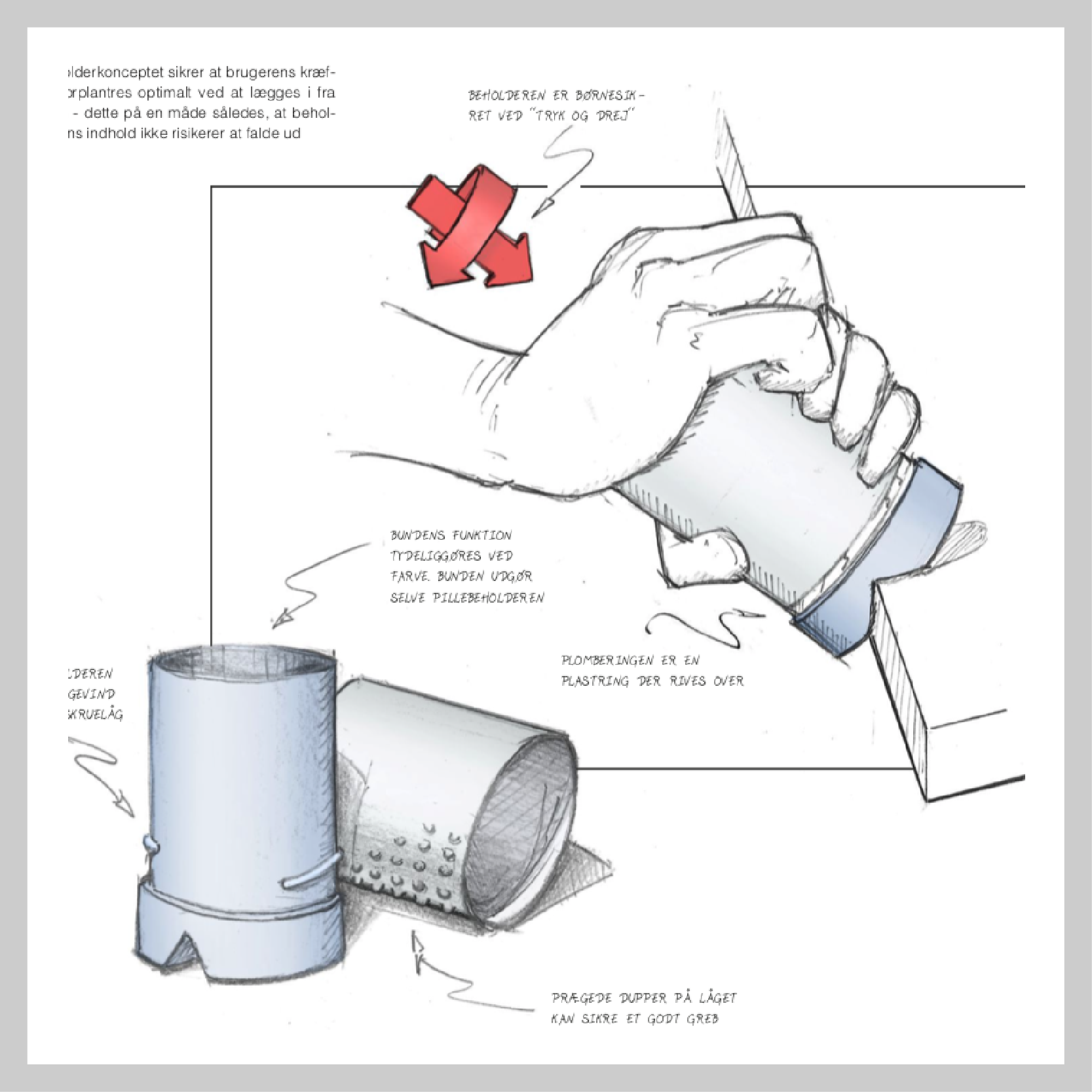

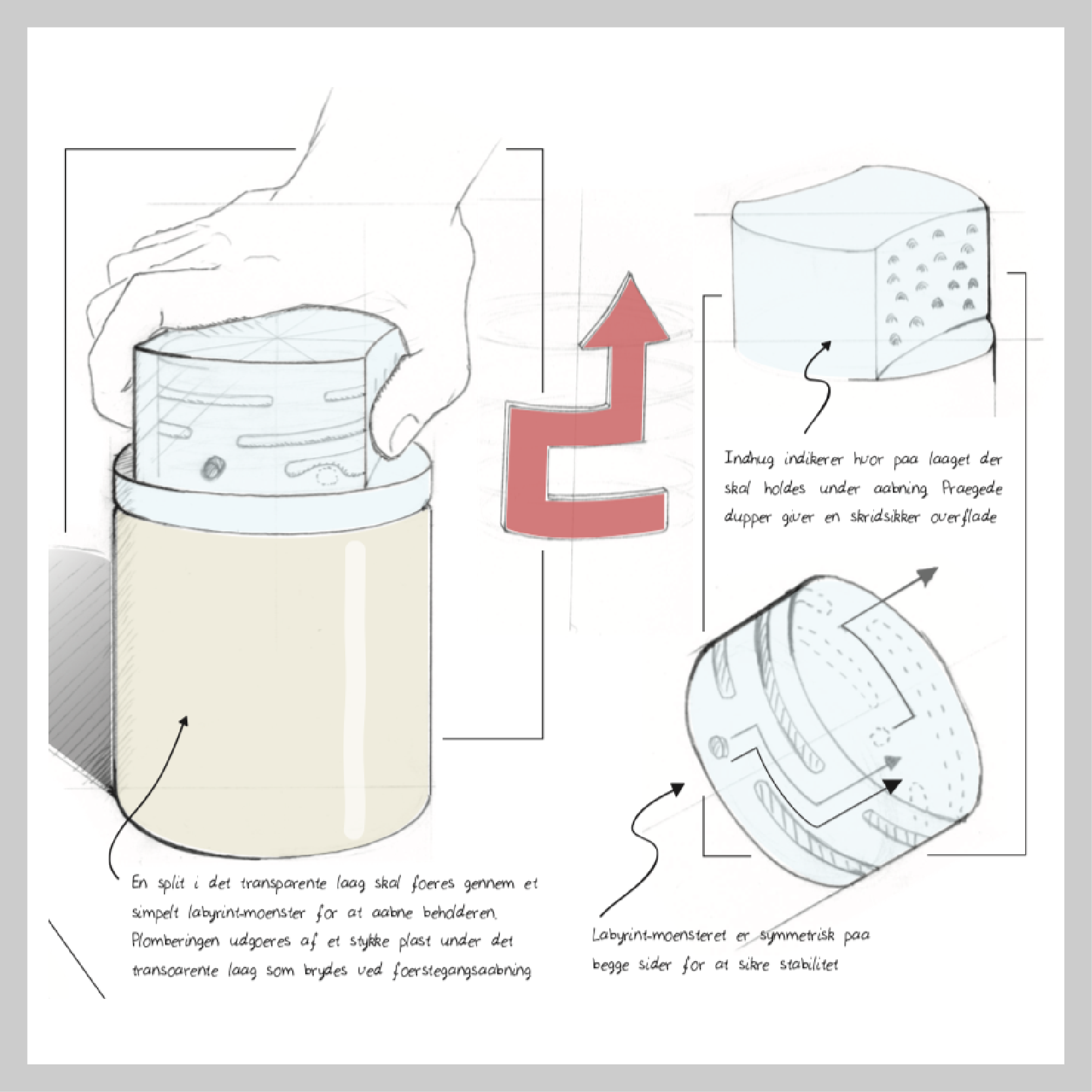

Through a series of brainstorm sessions, we created a number of ideas that were collected in categories according to the fulfillment of different sub-functions.

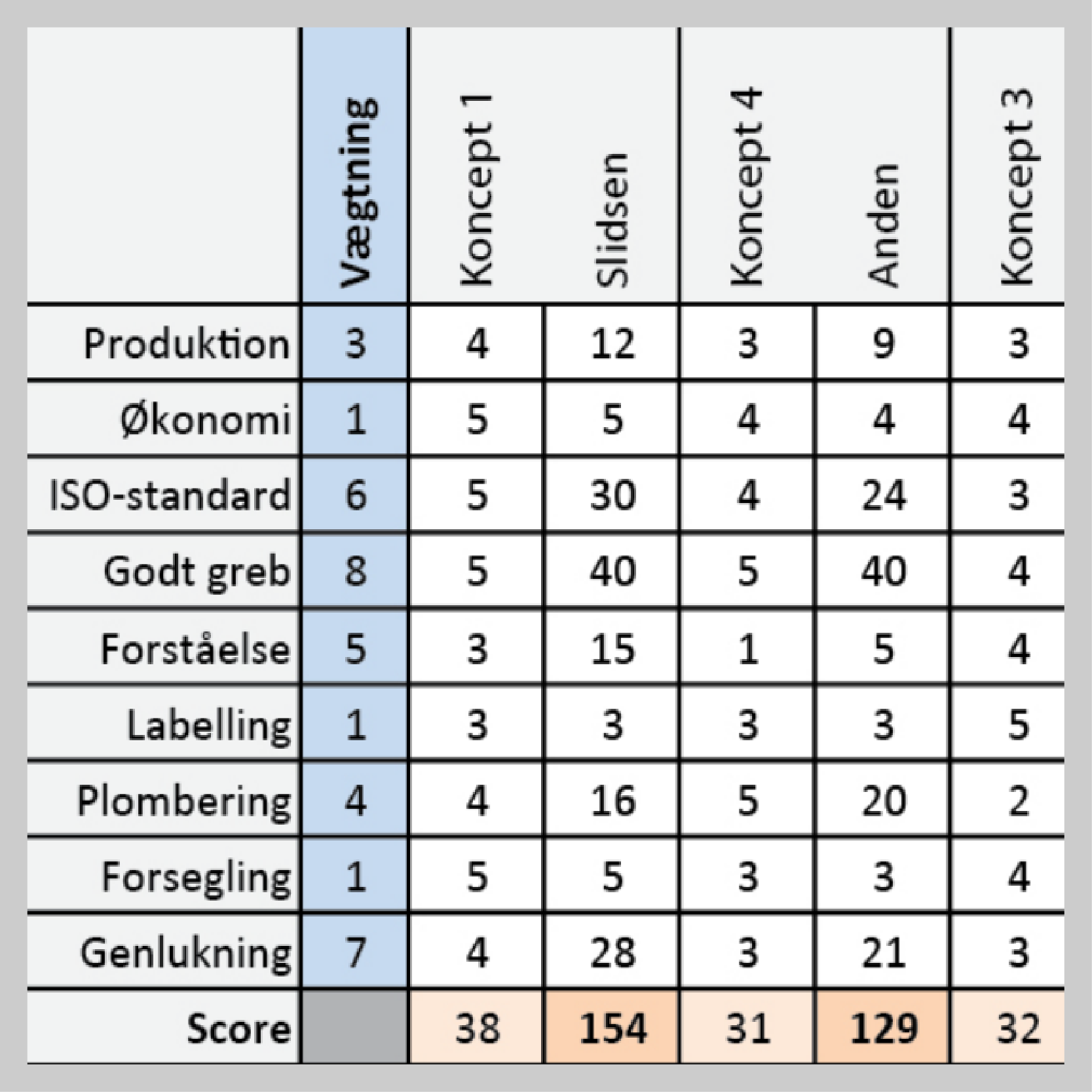

From the pool of ideas, we synthesized five concepts that seek to optimize the critical design parameters in different ways. They were systematically compared and evaluated by use of the Weighted Objectives method.

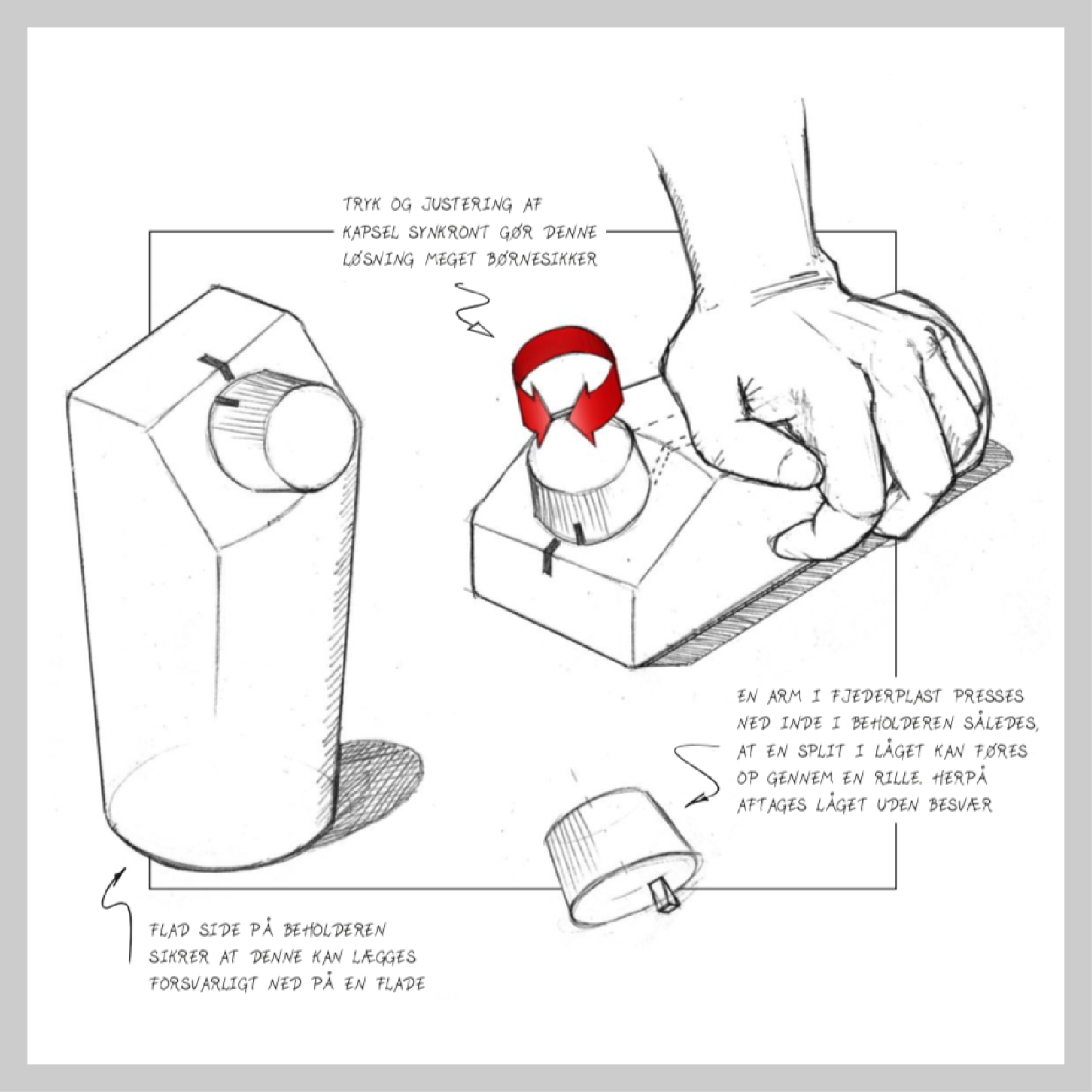

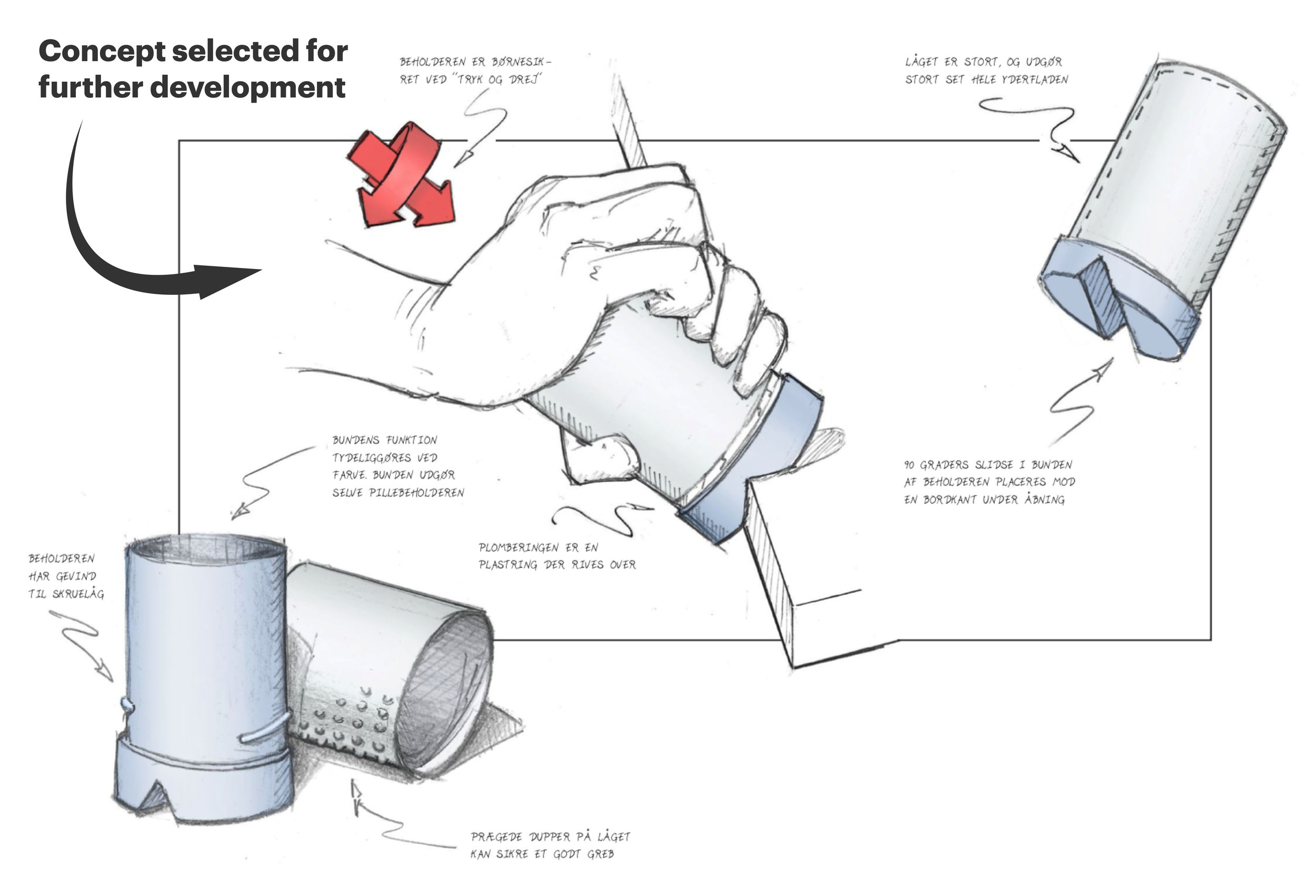

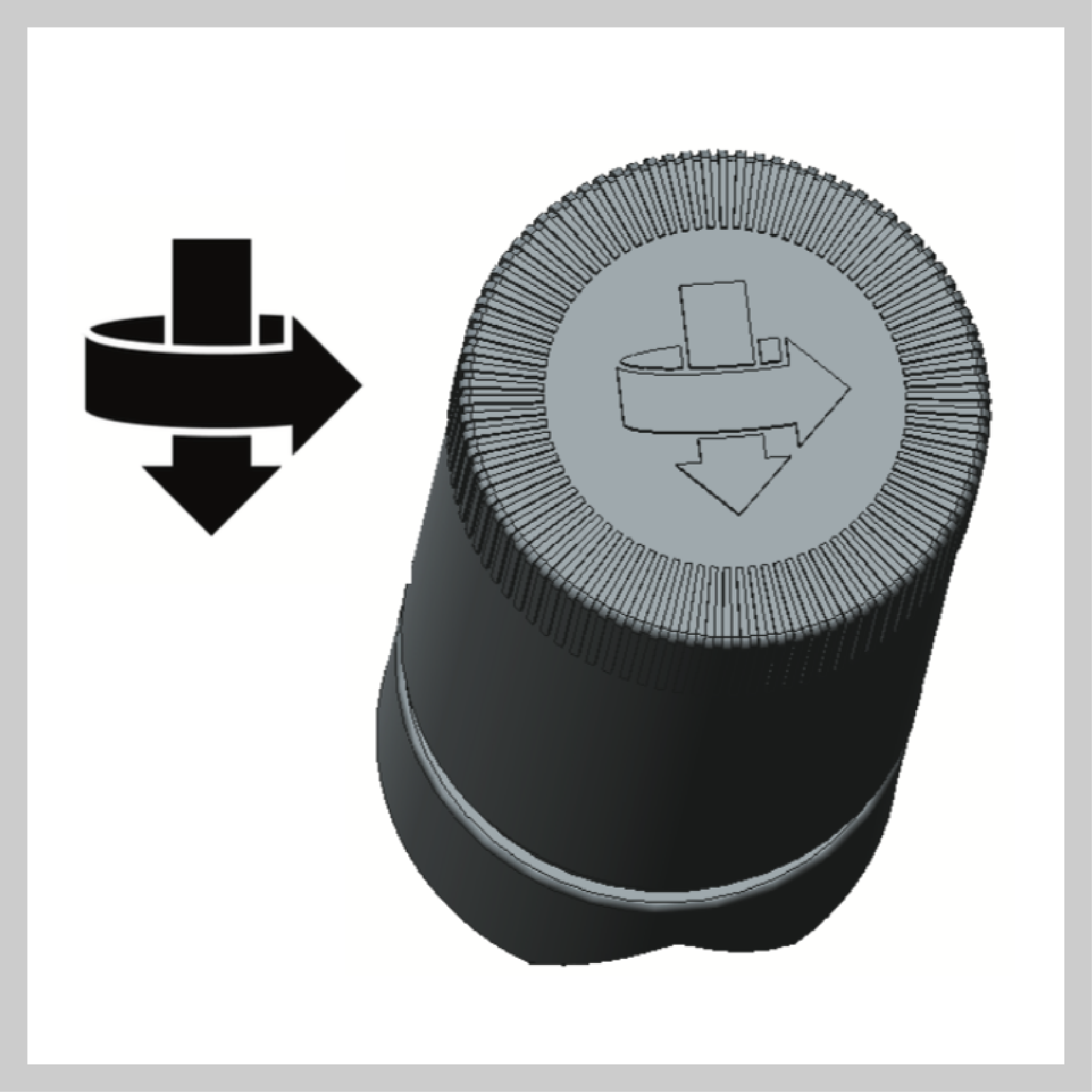

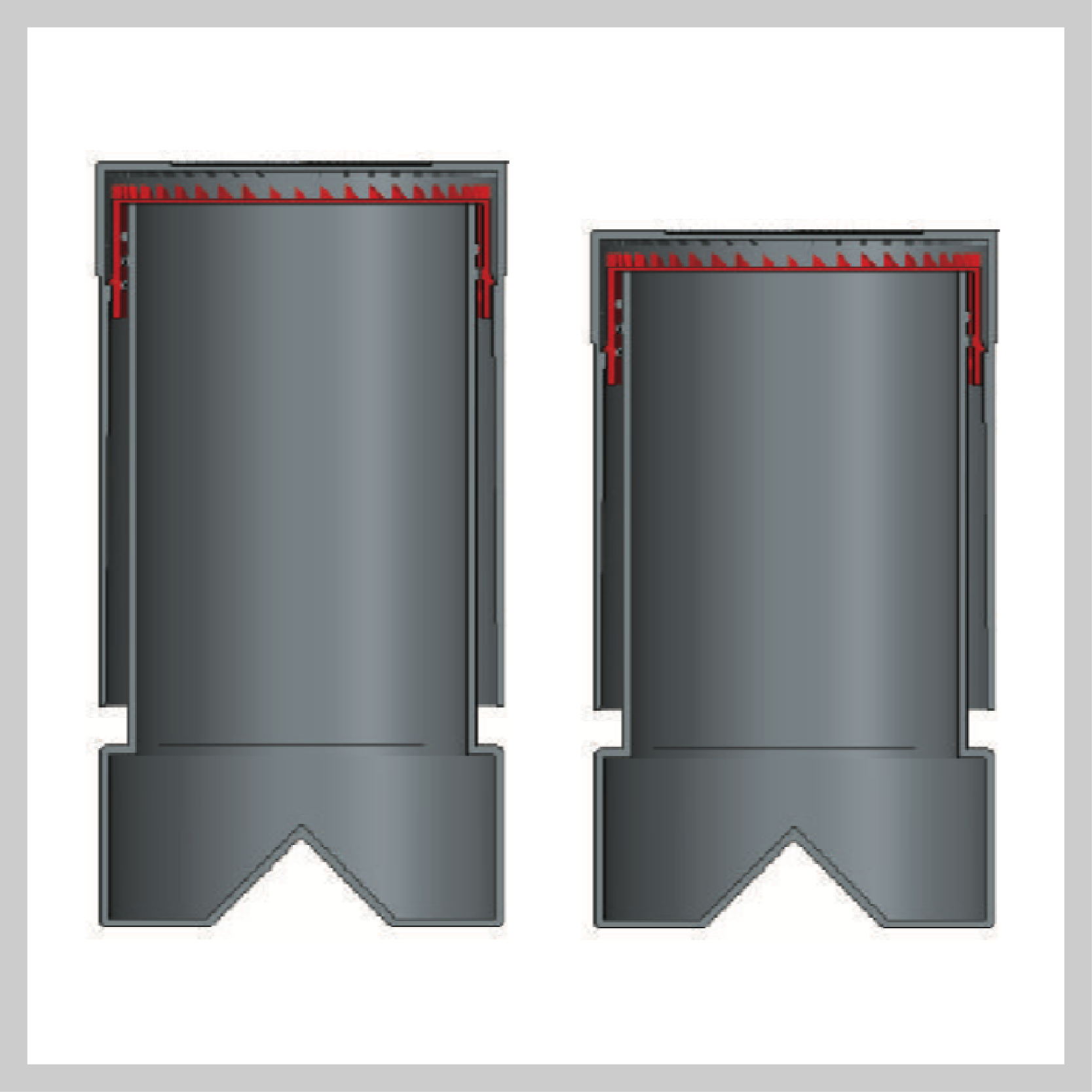

Based on the evaluation we decided on one concept to take into further development. This concept comprises a pill bottle with a lid that covers almost the full length of the container and a deep slit in the bottom that fits onto the edge of a table. These features allow the user to get a solid grip and use the strength of the entire upper torso without the pill bottle slipping.

Sketch by Jonathan Rasmussen

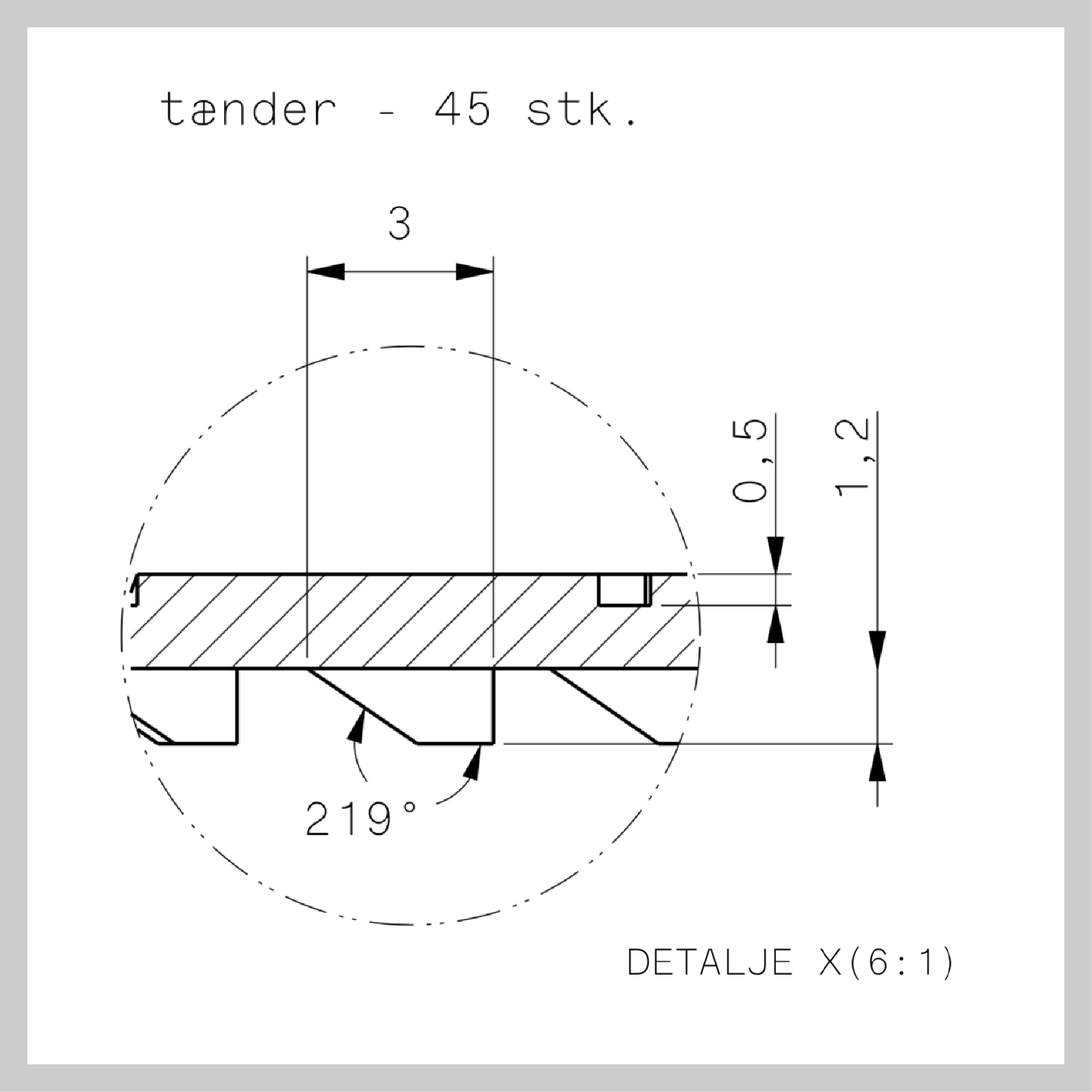

Design for Manufacturing

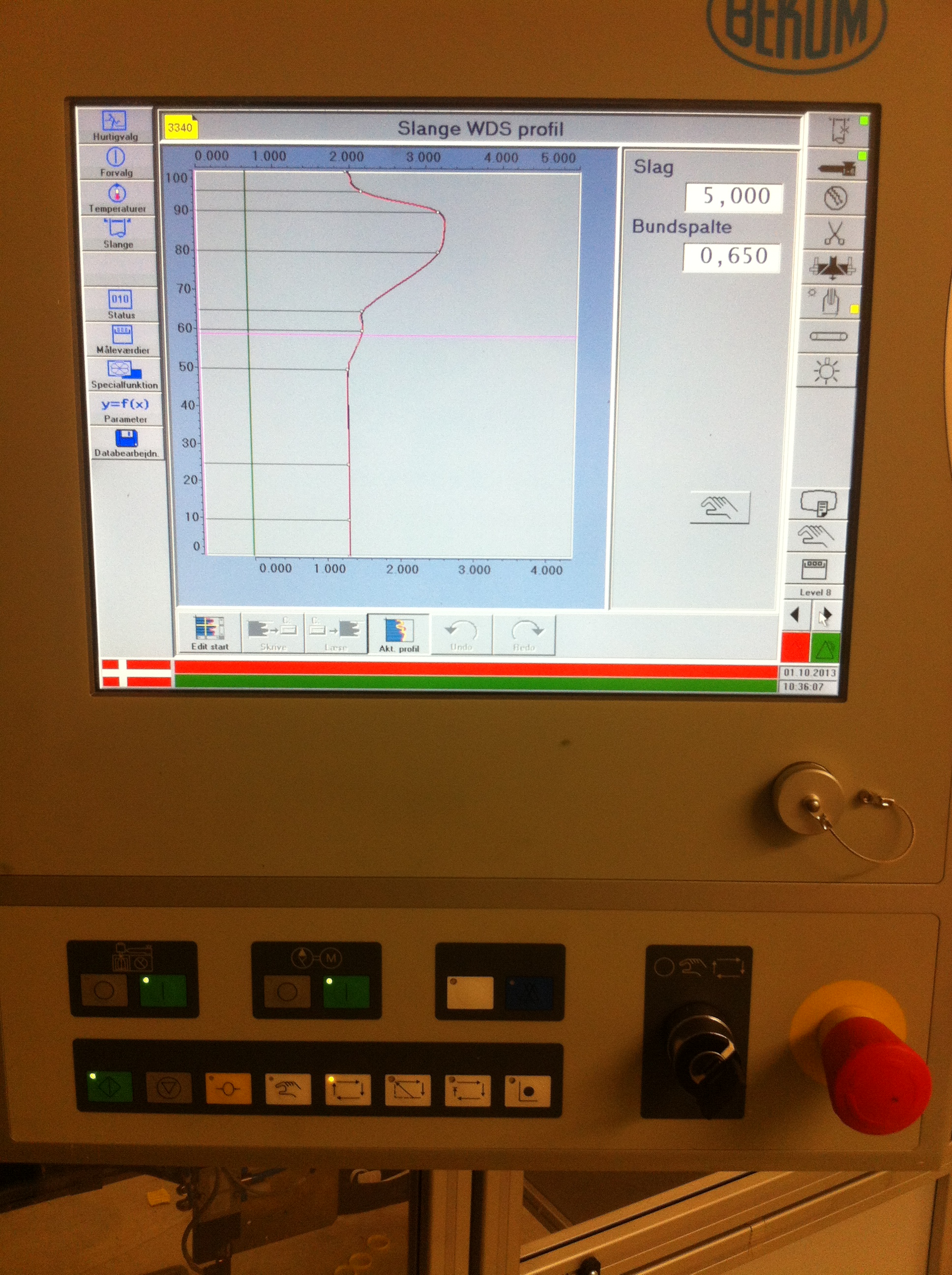

It was important for us to create a design that can actually be manufactured by our client. Therefore, we paid a visit to the factory of Novio Packaging A/S in order to identify both opportunities and constraints associated with their current production equipment.