Time of Execution

2016

Design Team

Camilla Arndt Hansen, Mads Ravn Mattiasen, Carmen Serrano, Dana-Maria Cobzaru, Frederik Hansen

Keywords

Plastics processing, DFM, injection moulding, mould design

Design Brief

Design of a USB stick with extra functionality and optimized for injection moulding.

Conceptualization

Since this project focused on later stages of product design where components are optimized for manufacturing, we did not put much effort into creating the initial concept. We quickly decided that a USB stick with a built-in safety cutter would be handy in our everyday work routines, and we stuck with this idea throughout the project.

We brainstormed to come up with ideas for how different functions of the design could be fulfilled. A single design solution was synthesized by combining ideas across functions.

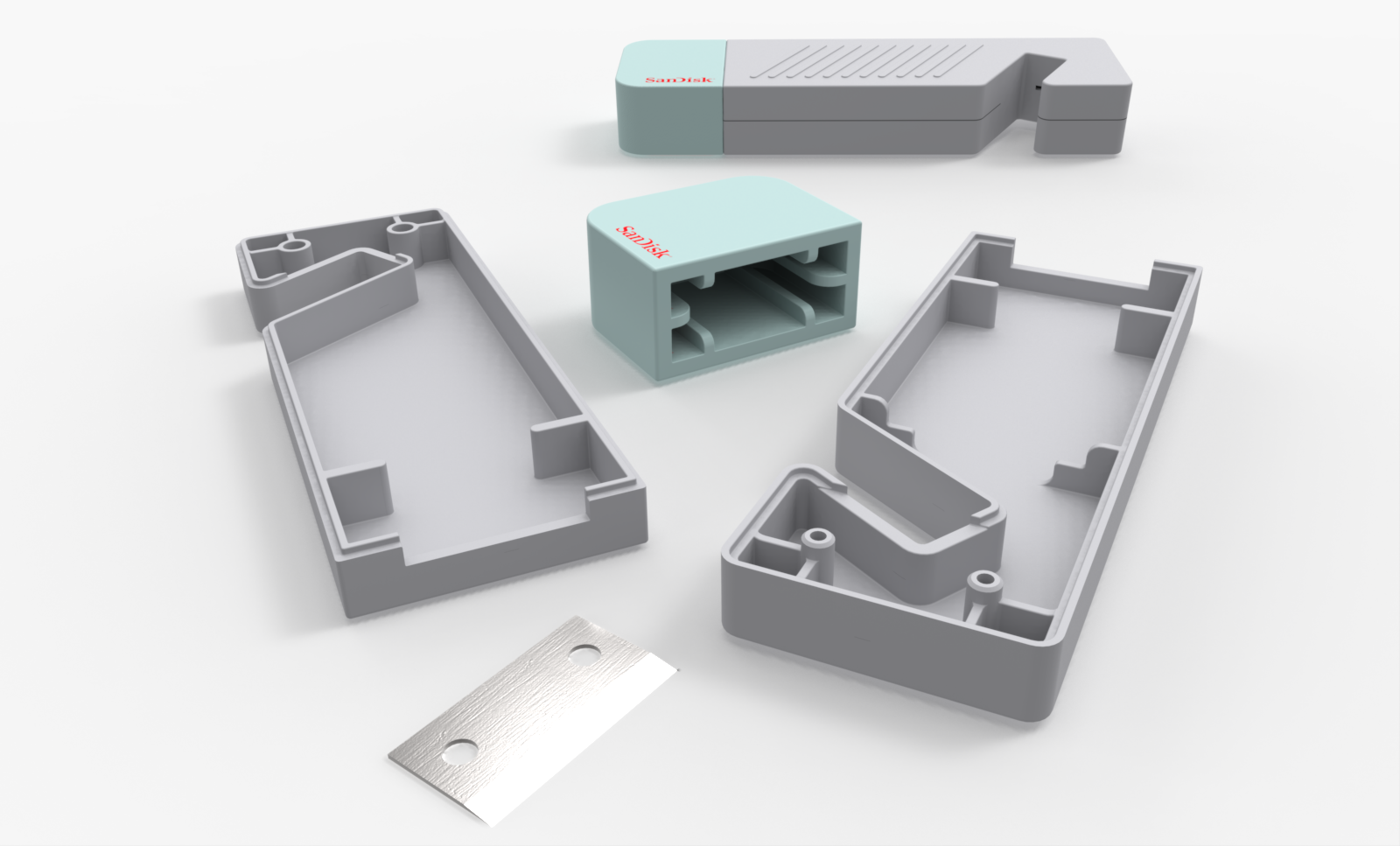

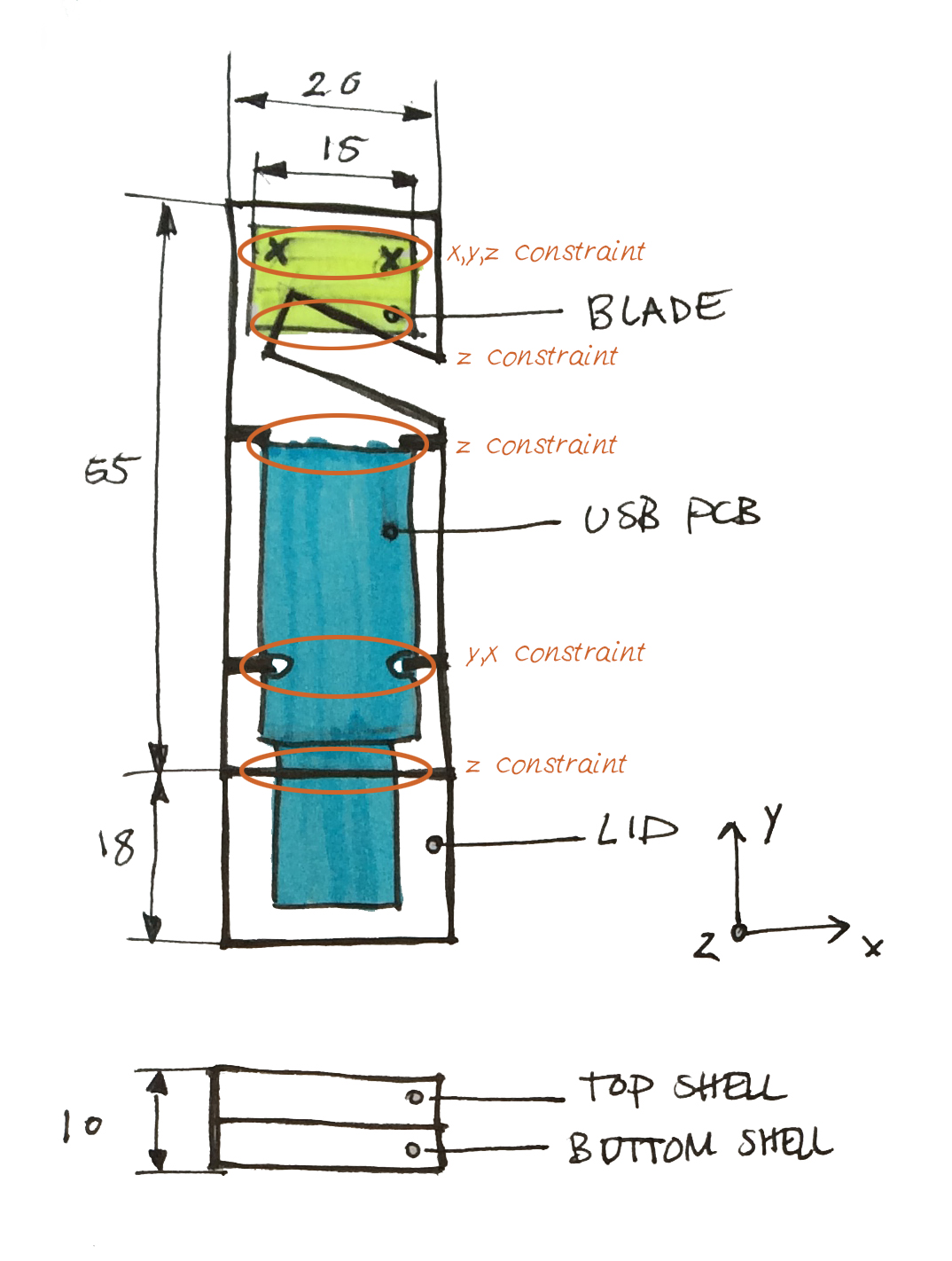

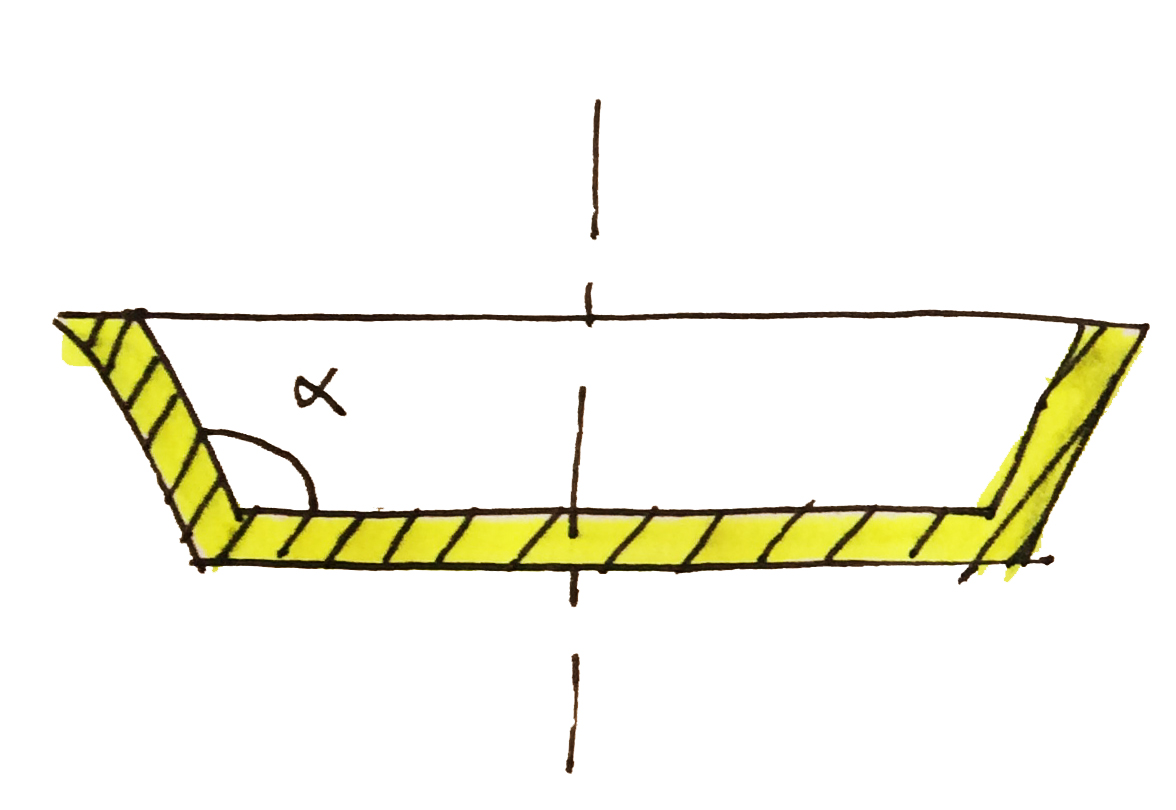

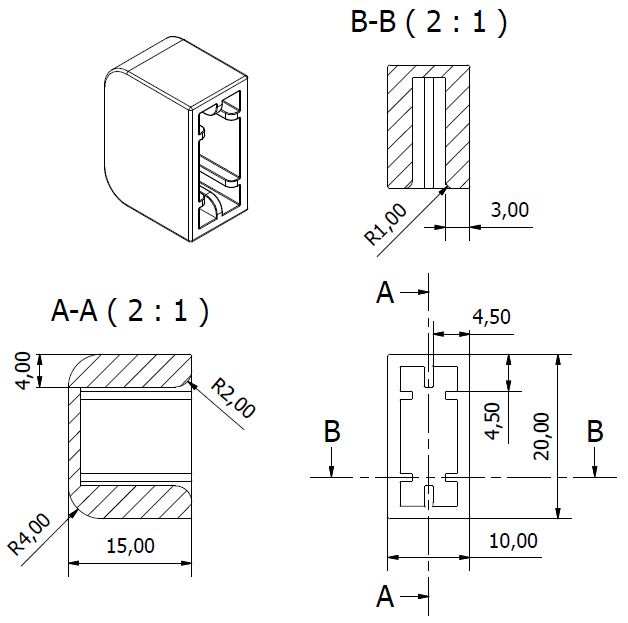

The final concept consists of two plastic shells which are glued together. During assembly, a small razor blade is sandwiched in-between two press-fit pins and a set of geometrical features secure the PCB in place. A press-fit lid protects the USB plug itself.

Sketch by Camilla Arndt Hansen

Material Selection

Before diving into the construction of the plastic parts, we set out to find the most suitable material. For this purpose we followed a 5-step framework.

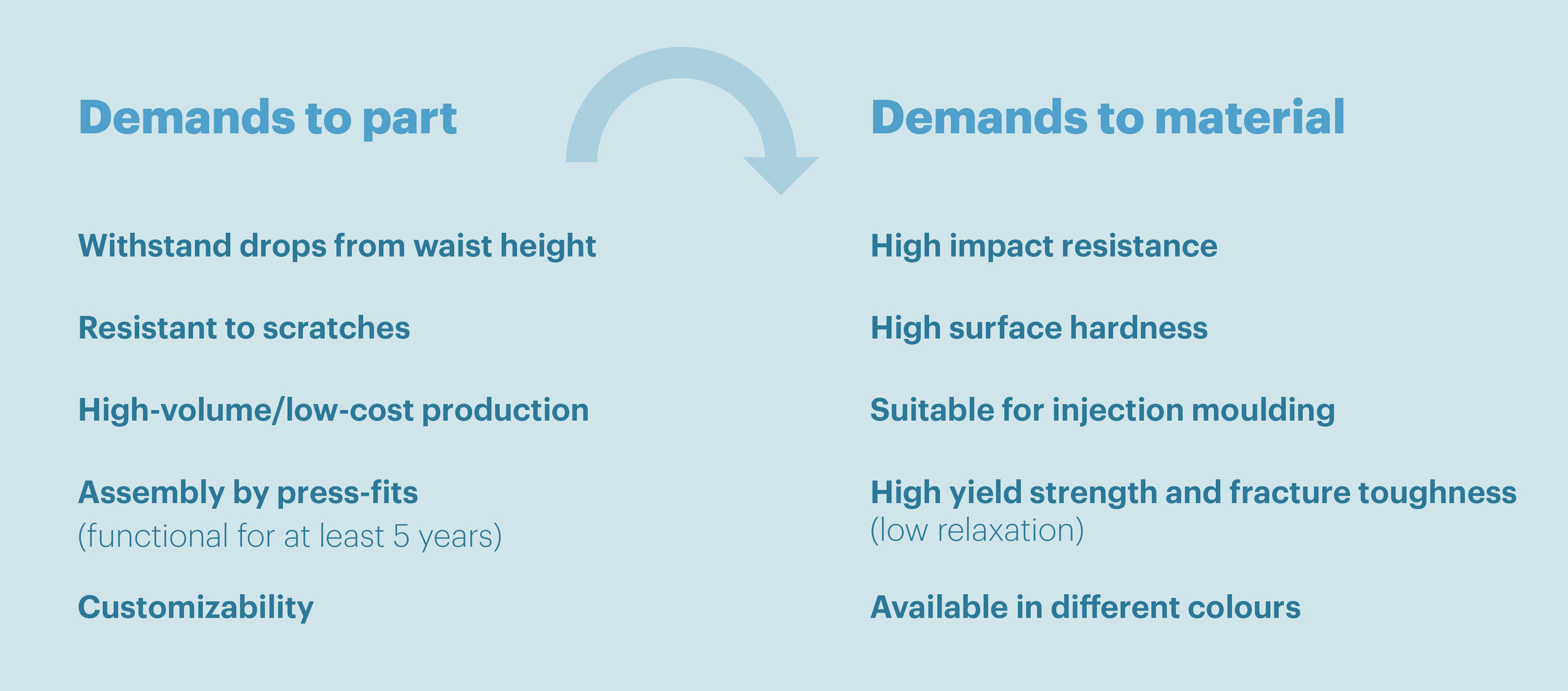

Establish demands for the part in relation to its planned use

Translate demands for the part into demands for the material

Divide demands to material into three categories

(qualitative, quantitative not related to thickness, quantitative related to thickness)Eliminate materials that do not meet demands

Select one material that meets demands most effectively

(e.g. cheapest alternative)